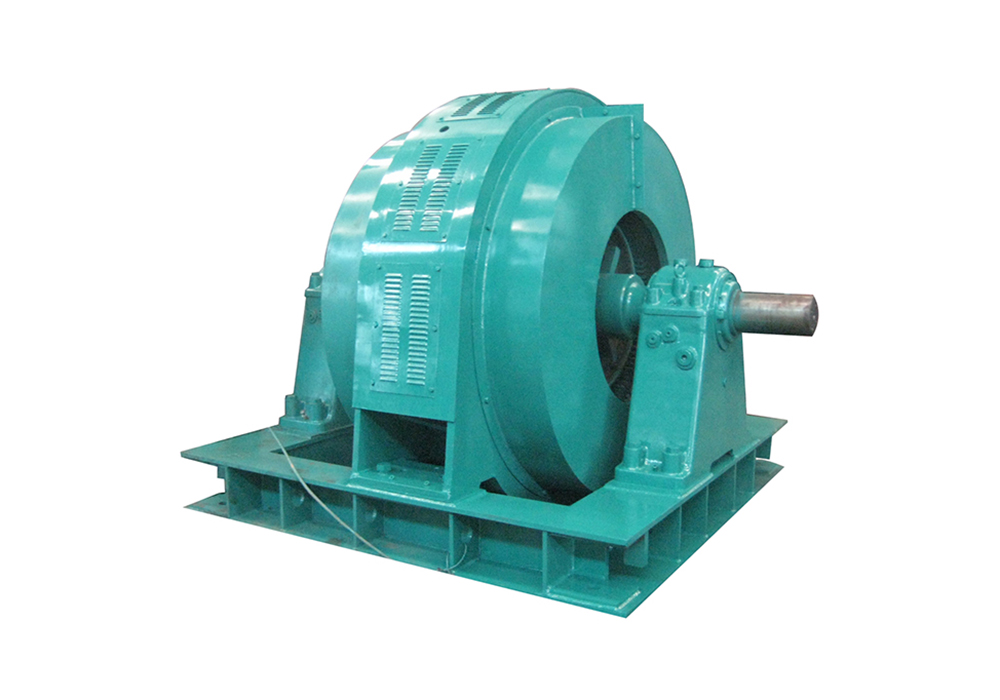

T series of large-scale synchronous motor have high speed , it is widely used in petroleum , chemical industry , electrical power industry and other industries to drive large moment of inertia such as ventilator , water pump , compressor , and etc., The rated voltage of this series of motor are 6KV , 10KV , or other voltage according to the customers’requirement , the rated power factor is 0.9 ( Leading ) . The motor allows to direct start as full voltage , the rotor circuit should be connected in series with 10 times magnetic winding resistance when starting .

T series of synchronous motors are of horizontal structure . Its cooling type includes water cooling type , open self-fan cooling type , pipeline or semi-pipe line ventilation type , and enclosed self-circulation ventilation type . this type of synchronous motor can be made into one end shaft extension or two ends shaft extension . The direction of rotation is anti-clockwise view from the slip ring end . the direction rotation can be changed according to customer’s requirement , but the blades of the motor should be changed accordingly .

The motor frame is welded with steel plate into integral structure , the motor frame and bearing seat are respectively fixed on the bottom plate welded by the steel plated . the stator core is laminated and punched with 0.5mm silicon steel plate , and stator core is fixed on the motor frame by tightening screw . The stator coil is lap winding , it adopts F insulation material , and anti-corona measures . The coil ends have reliable fixed binding and are treated via vacuum pressure impregnation (VPI) paint . The magnetic pole are laminated with magnetic pole punching plate made of thin steel plate , magnetic pole core is sheathed with magnetic pole coil . The entire magnetic pole is mounted on the magnetic yoke . the magnetic pole coil is made of copper rectangular wire ,which is F level insulation after insulation treatment . The bearing is composed of a cast iron bearing seat and a bearing shell poured by a bearing alloy . The lubrication method is oil ring self-lubrication or compound lubrication of external oil circuit system . The slip ring is assembled structure , the brush is installed in the constant voltage brush box , connected by a conductive plate , the entire brush holder is fixed on the side of bearing . The excitation system of this series of motors adopt silicon controlled excitation device , which can be provided by our company .

The power level , installation dimension , electrical performance of this series of motors are in accordance with the national standard GB755-2000((rotated motor rating and performance )) , the mechanical industry standard JB/T10315.2 and relevant standard IEC60034-1 . At present , the product has low energy consumption , stable operation , which has been widely recognized by customers in the market .

Applications

The motor are used for driving large machines with constant speed such as ventilator , compressor , ball mill , water pump , rolling mill , and etc.,

Working Condition

Power : 160kW~12000KW

Voltage : 380V-13.8KV

Rated frequency : 50HZ

Pole :10P~24P

Protection class :IP00 ,IP23

Cooling type : IC01

Insulation class : F

Temp. rise :B

Ambient temp. :-15℃~+40℃

Altitude :No more than 1000M

Service factor :1.0

Working duty :S1

Mounting type :IM7311